Plastic processing as a business solution

Not everyone knows that household waste processing, including plastic bottles (and other tableware) can generate income. However, it is estimated that during the next 20-30 years any business based on waste and salvage processing will be highly viable. This opinion is based on the fact that: plastic has such qualities as lightness and profitability. Its production is not expensive, and obviously raw materials will always be available to business. Besides, as secondary processing of plastic products begins to develop the State is ready to support businessmen in this sphere in every possible way.

Utilisation of plastic bottles assumes their processing for the purpose of reuse or other materials production. The technology is not difficult and consists of the following stages:

- Collecting and sorting. This stage means the organisation of plastic acceptance sites, special designated collection points for the purpose of raw material sorting process simplification and agreements with landfill operators or processing plants.

- Crushing. This agreement preparation stage is carried out with use of rotor crushers therefore receive the chipped flake pieces of a certain size named by PAT-flex.

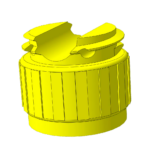

- Cleaning. The crushed waste comes in first to be jet washed, then further cleaning is done in stages, using the special washing mixes, consisting of, for example, caustic soda. Then separation is carried out in the special centrifugal drum, and the washed-out mass of paper stickers, polypropylene labels and covers are erased with flotation. After that, flex repeatedly is washed with ordinary water and moved to the dryer.

- Agglomeration. The splintering into small crumb lumps is carried out at this stage.

- Granulation. It is the final stage of salvage preparation for further processing. During the granulation process material is condensed, transformed from plastic lumps to grains of a specific size that facilitates further processing. Granulate is used for making packing, construction details, film and many other things.

Thus, the processing of plastic bottles is useful not only in terms of ecology, but also financially profitable. A correctly built business will ensure owners gain a stable, high income, and at the same time vastly improve an ecological situation.

I was pretty pleased to find this great site. I want to to thank you for ones time just for this fantastic read!! I definitely really liked every little bit of it and I have you book-marked to see new stuff in your blog.

You have put so much thought into the manufacture of designing a unique version of an old product that is used by almost everyone worldwide on a daily basis, and at the same offering solutions to the problem of what to do with single-use waste. I wish you every success with this new venture!